Smart measurement technology for tanks and containers in the food and beverage industry

Tanks play an essential role in the food and beverage industry. Whether they’re used as storage tanks, cooking and boiling vessels, buffer tanks, mixing tanks, vacuum tanks, batch tanks, collection containers or mobile tanks – their reliable functionality is crucial for smooth production processes. In order to meet the different requirements of your applications, we offer you customised measurement solutions that are specifically tailored to your needs.

Benefit from the advantages of our measurement technology for your tanks

Discover WIKA’s measurement solutions for your tanks

WIKA offers a wide portfolio of measurement solutions specifically developed for the requirements of your tank applications in the food and beverage industry:

Level measurement:

Our level sensors offer you precise and reliable measuring results to efficiently monitor your stock.

Pressure monitoring:

The UPT-21 process transmitter features a robust and hygienic design and ensures reliable measuring results, even under demanding process conditions.

Temperature monitoring:

The TR20 resistance thermometer offers accurate temperature measurements and fulfils the highest hygiene standards.

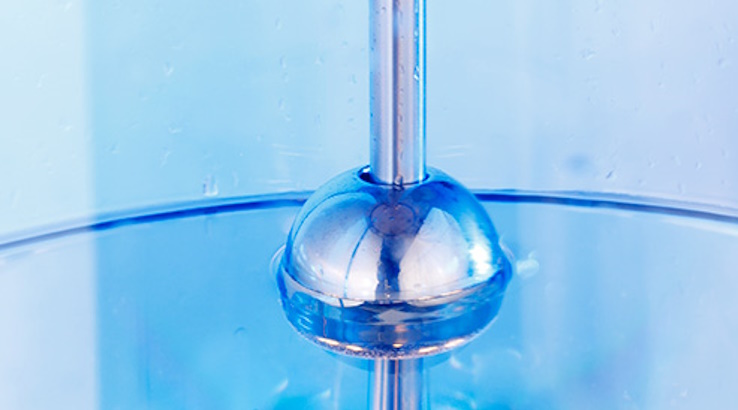

Highlight for mixing tanks: Optimum temperature measurement with the TR20 resistance thermometer

The TR20 resistance thermometer has been specifically designed for use in mixing tanks. With its flush BioControl® connection, the TR20 is deal for applications where conventional thermowells immersed in the process medium are considered to be impractical or undesirable. The design of the TR20 meets stringent hygiene requirements and ensures improved cleanability. This makes it particularly suitable for use in mixing tanks.

- Hygienic design for easy cleaning: The flush design minimises dead spaces and facilitates cleaning, thus avoiding process contamination.

- Fast response time for precise control: The ground-level sensor installation enables a fast response time and ensures accurate process control.

- Highest measurement accuracy: Our sensors provide precise measured values for an optimal control of your processes.

“WIKA offers you customised measurement technology for your tank applications. Our technologies ensure precise level measurement, precise temperature control and reliable pressure monitoring – even under difficult conditions such as foaming, high viscosity and intensive cleaning processes.”

Joachim Zipp, Global Market Segment Manager

Project examples: How our customers benefit from our solutions

Process transmitters in dairy production

Temperature monitoring in brewery tanks

Level and temperature in yeast production

Level measurement for vinegar production

Latest blog posts

Further information

Talk to our experts – customised measurement solutions for your tank applications

Contact us to find the optimal measurement solution for your specific requirements. Our team is at your disposal to make your production processes safer and more efficient.