Smart measurement technology for silos in the food and beverage industry

The food industry is enhancing efficiency and sustainability by refining processes such as raw material logistics and using gravimetric level measurement technology for continuous monitoring of storage silos for materials like grain. This ensures deliveries match actual needs, with timely orders based on level forecasts. This prevents downtime, optimises resource usage and reduces CO2 emissions. By focusing on precise level measurement and pressure and temperature monitoring, the industry balances operational efficiency with environmental responsibility, maintaining high safety standards.

Benefit from the advantages of our measurement technology for your silos

Gravimetric level measurement (weighing technology)

Gravimetric level measurement offers a sophisticated solution by determining silo levels through weighing and effectively monitoring silo contents. This offers a non-invasive, highly accurate way to detect weight and level without material contact. This is especially useful where robustness, storage life and sterility are critical in storage silos.

A key advantage is that operators can measure both the level and exact mass, ensuring highly accurate weight determination regardless of the material or silo shape. The method is suitable for containers of all sizes, from small to large silos, handling capacities up to 1,200 tons while requiring minimal maintenance.

Discover WIKA’s measurement solutions for your silos

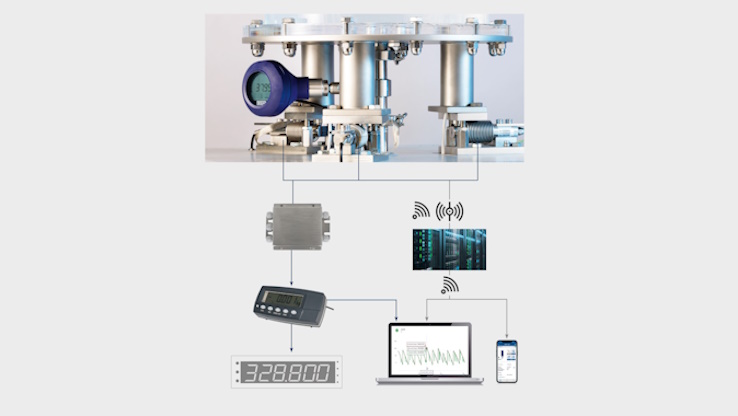

The design of a gravimetric level measurement system is pivotal in combining precision with technological advancement. The load cells as core components are used for weight measurement, which can be displayed as fill levels.

There are two connection options:

- Traditional connection: The system incorporates load cells that can be wired to a junction box, which compiles and displays the material’s weight within a container.

- Integration of wireless technology: Load cells can also be equipped with radio modules that enable wireless data transmission to a cloud platform, thus facilitating easy data access and visualisation.

The gravimetric level measurement system is comprised of shear and bending beam load cells, complete with mounting kits for easy implementation, and can be connected to a junction box. This setup allows the measurement data to be transmitted either directly to a display for immediate reading or wirelessly to a cloud platform for further processing and visualisation.

WIKA offers a comprehensive range of weighing technology solutions for gravimetric level measurement as well as for pressure and temperature monitoring. Product highlights include:

- The MA diaphragm pressure switch for pressure monitoring and control of processes is specifically designed for safety-critical applications. The robust switch enclosure (IP66) made from aluminium alloy can withstand the rough and corrosive operating conditions of the process industry with operating ranges of up to 600 bar. The enclosure cover can be secured against unauthorised access with screw locking.

- The TR10-B resistance thermometer with versatile sensor options (Pt100 or Pt1000), various connection heads and adjustable lengths paired with the TW25 thermowell ensures precise temperature measurements in harsh environments.

„Our gravimetric measuring systems enable high-precision level and weight determination through direct mass measurement and provide reliable data for efficient process control in silo applications.“

Jonas Naumann, Product Manager – Force and Weighing

Project examples: How our customers benefit from our solutions

Accurate control of the weight of the yeast tank

Safeguarding of food silos

Latest blog posts

Further information

Contact us

Do you have any questions? Simply use the following form. We will be pleased to help you!